Some Of Sheroz Earthworks

Table of ContentsFacts About Sheroz Earthworks RevealedThe smart Trick of Sheroz Earthworks That Nobody is Talking AboutSheroz Earthworks Can Be Fun For EveryoneGetting My Sheroz Earthworks To WorkThe Ultimate Guide To Sheroz Earthworks

For any type of earthwork specialist, it is important to carry out deal with high quality, accuracy, and on routine. Making use of equipment control in work makers allows maximizing the various phases in the earthwork procedure, from planning to the upkeep stage - topcon. The device control system assists the machine driver in acquiring the target aircraft promptly and conveniently

The equipment control system guides the driver with centimeter precision. With Xsite PRO 3D, you'll always recognize precisely just how much to cut or load. Your regional Xsite technical support can direct you and aid with any kind of issues without checking out the site. Remote support conserves time and cash, as it lessens downtime in jobsites.

Some Known Details About Sheroz Earthworks

Added training and guidelines are constantly readily available over remote assistance when required. The earthmoving sector has actually used our field-proven solutions because the early 1990s. Our system's parts are thoroughly developed to hold up against the harsh problems of building and construction websites. Contrast of the same project performed utilizing maker control versus the standard approach discloses that, usually, the traditional approach requires 50% more time to accomplish the exact same job as the technology-assisted technique. https://www.giantbomb.com/profile/sherozau/.

Get in the Xsite device control system; it's right here to supply you with a significant advantage when functioning with earthmoving machinery. Discover just how Xsite Machine Control can improve your productivity and guarantee work safety! Xsite Machine Control systems can be mounted to any type of excavator from mini excavators to big mining excavators.

How does maker control work? In 2D systems, the machine is equipped with adjusted inclination sensors. These sensing units are installed on the pre-determined parts of the equipment in excavators the sensor are usually placed to the framework, boom (or booms), digger arm and to the fast coupler - topcon gps. By making use of the data received from these sensing units the system can calculate the specific setting of the excavators bucket idea in significance to a reference factor.

The system is very easy to discover the essentials can be educated in under one hour of training. Just how does the remote support work? A wireless web link makes it feasible to establish a remote connection between the maker control system and the solution.

The 10-Minute Rule for Sheroz Earthworks

Xsite Machine Control systems sustain open typical documents styles, allowing seamless information circulation from one system to another. Depending on your selection of system (with or without placing, i.e., 2D or 3D), your equipment is outfitted with disposition sensing units, a controller system, and a display/operating panel.

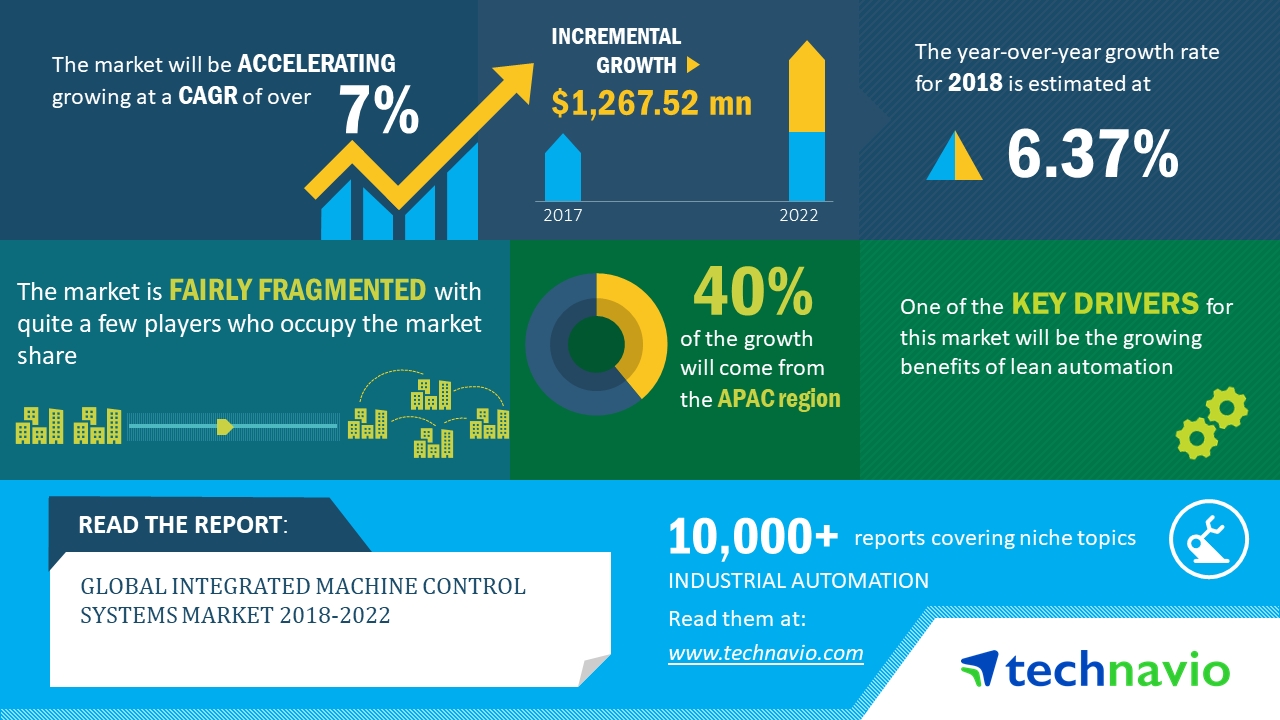

Lots of equipment and software services exist to help determine an equipment's existing placement on the planet and contrast it with a wanted layout surfaceand building and construction operators can do even more to take advantage of the advantages. Equipment control is using various positioning sensors and a screen to give the operator with a recommendation between the setting of the container or blade and the target quality.

Relying on the setup, machine control systems can provide the driver with a straightforward aesthetic guide to bucket or blade setting, or can automatically move the blade to quality by talking with the equipment's hydraulics - https://zenwriting.net/sherozau/sheroz-earthworks-pty-ltd-and-sheroz-hire-pty-ltd-est. There are maker control systems readily available for just regarding any maker: graders, dozers, excavators, dirt and asphalt compactors, scrapers, trimmers, milling equipments, and pavers

The Ultimate Guide To Sheroz Earthworks

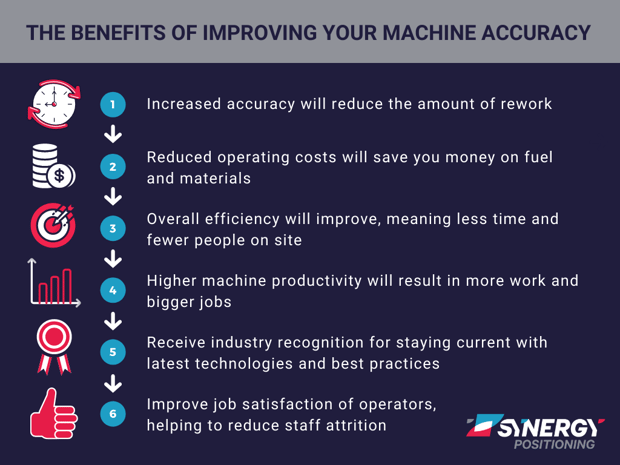

Device control can additionally help increase performance and lower total costs. Construction equipment without device control will certainly become a point of the past and the advantages acquired from it will be countless.

Trimble equipment control systems provide a myriad of benefits company website to anyone that uses earthwork machinery and, at EarthCalc, we can offer you with 3D apply for your machine control-enable tools. Unsure if equipment control deserves the expense? Think about the complying with reasons you need to consider this choice.

Utilizing GPS lined up with your 3D layout data, these systems essentially assure that you will get rid of or place the right quantity of product at the building and construction website. On many construction sites, remodel is an usual and discouraging fact, however with Trimble equipment control, you can get rid of the demand for rework.

Sheroz Earthworks Fundamentals Explained

Frequently, with Trimble maker control, you can get rid of excess equipment at a certain job site. A job that might have called for the usage of 3 or four items of excavating devices now could require just 2 items of equipment to achieve the very same task in less time. This permits you to move your equipment to an additional job website and manage numerous work at once.